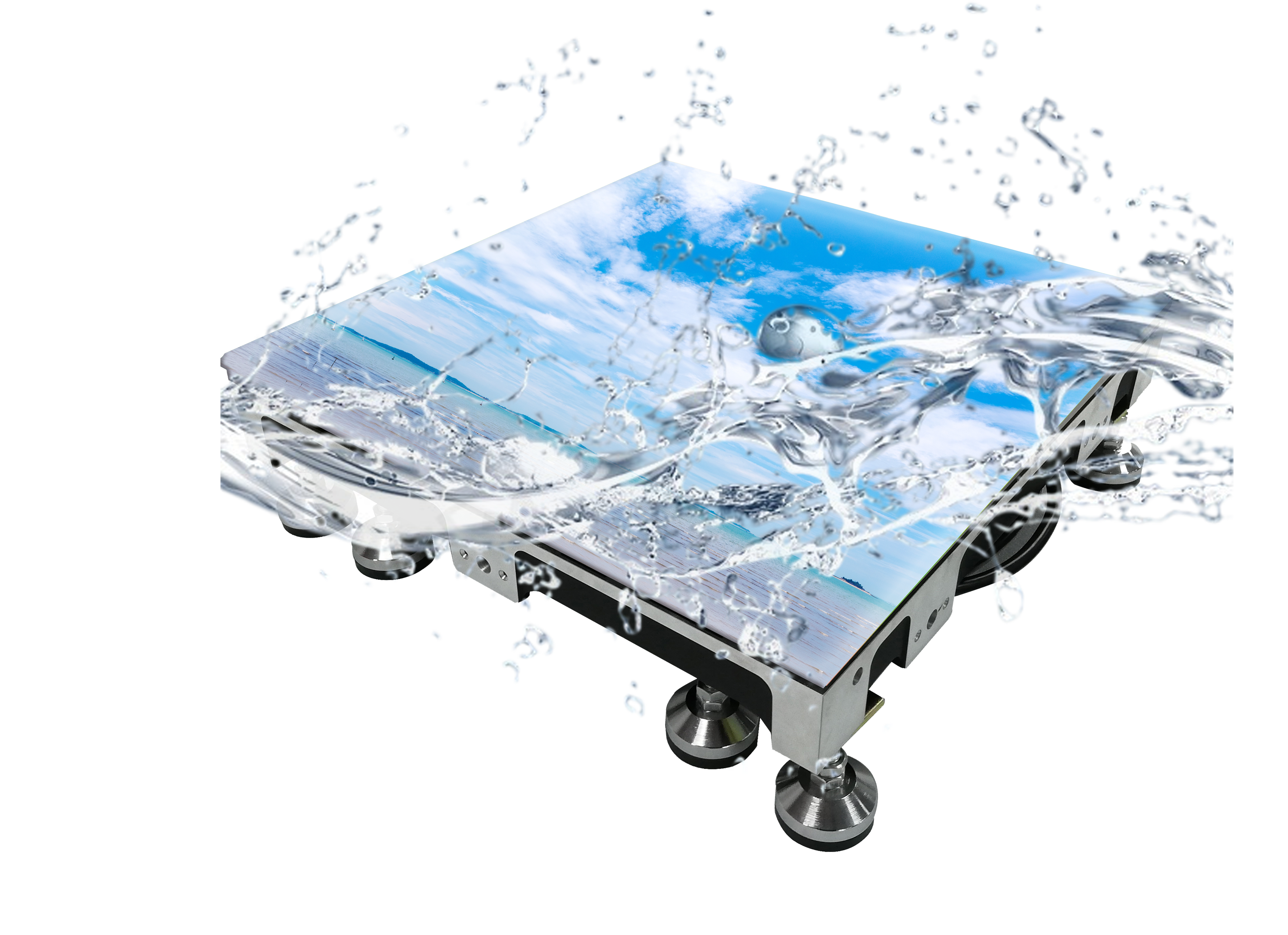

Rental LED Floor Display Indoor & Outdoor Lightweight Front Maintenance Fast Installation

The floor screen independently developed byRingsunLED adopts PC material (carbonate-based polymer) imported from Germany, which has high strength and elastic coefficient, high impact strength and good toughness. It can be used in a wide temperature range. High transparency and free dyeability: light brown or dark brown can be freely selected. Low molding shrinkage: good dimensional stability, low coefficient of thermal expansion and contraction.Good fatigue resistance: increased adhesive, good toughness, not easy to crack after repeated use. Good weather resistance: It is not easy to change color or crack under the change of temperature.Customized private mold, adding water guide groove, non-slip surface. The surface is frosted, wear-resistant and scratch-resistant. Increase the diffusion agent to achieve anti-dizziness, anti-UV, and increase the safety of guests.

The floor screen needs to be waterproofed regardless of whether it is indoors or outdoors. Our company's indoor modules completely adopt outdoor standards. The screw holes are sealed with three-proof glue to ensure moisture-proof,waterproof and dust-proof to the greatest extent. The waterproof and dustproof coefficient of the surface can reach IP54 for the indoor model, and the front and back of the outdoor model have IP68 protection level.The number of load-bearing columns in each module is as many as 71, and adhesives are added to the material to ensure the toughness and strength of the load-bearing columns, not only can it guarantee the weight of 2600KGS/SQM, but it can also ensure that the tension generated when the heavy object goes up and down ensures that the column does not break (the tension will cause the column to break, and after the break, the module will crack when the weight is removed and put on it again) .

In order to ensure the load-bearing requirements, the module is designed as a suspended structure of the light board, and the load-bearing columns on the mask passes through the holes on the light board and directly inserts into the load-bearing holes of the bottom case. When the surface of the screen is under pressure, the pressure directly reaches the bottom case of the module through the load-bearing columns and then is distributed to the panel. The stress-bearing parts of the cabinet are desianed with stiffeners to distribute the force on the surface evenly on the entire panel to the greatest extent, rather than at several points. Die-cast aluminum material better guarantees heat dissipation.Waterproof beading is used around the back cover to ensure that water vapor on the ground cannot enter the control box. The floor support is made of galvanized floor support instead of hard plastic, which increases the load-bearing effect.

The structure of the die-casting aluminum panel is designed to be installed on the wall and the ground. Each panel weighs 11kg. It is equipped with positioning pins and quick locks, which makes installation more convenient and has high installation accuracy. The consistency is good, and one type panel supports two installation methods, which is more cost-effective. The ultra-high-definition seamless stitching solution customized for XR and Film has received widespread attention and recognition around the world.

20+ YEARS

Industry Experience

3000 KGS/㎡

Load Bearing

2 YEARS

Warranty

100+

Country

200+

City

1000+

Project

ISO9001, CE, RoHS, FCC, CCC, UL, EMC.

Private model customized modules and cabinets.

Screen heights can be customized.

PC housing, anti-slip, anti-glare, wear-resistant, UV resistance.

Maximum load capacity of 3000 KGS/m^2.

Customized maintenance tool.

Cabinet material can be selected.

Lifespan over 100000 hours, 2 years warranty.

Complete test reports and certificates.

Multi-equipment linkage, better audiovisual effect.

|

Model |

P2.5 | P2.604 | |

|

Module

|

Pixel composition | SMD LED 1R, 1G, 1B | SMD LED 1R, 1G, 1B |

| Pixel pitch(mm) | 2.5(W)×2.5(H) | 2.604(W)×2.604(H) | |

| Module resolution(W×H) | 100×100 | 96×96 | |

| Module size(mm) | 250(W)×250(H)×16(D) | 250(W)×250(H)×16(D) | |

| Module weight(kg) | 2.1 | 2.1 | |

|

Steel Cabinet

|

Unit cabinet size(mm) | 500(W)*500(H)*78(D)、500(W)*1000(H)*78(D) | 500(W)*500(H)*78(D)、500(W)*1000(H)*78(D) |

| Cabinet weight | 44 kg(500(W)×500(H)×78(D) | 44 kg(500(W)×500(H)×78(D) | |

| (kg/㎡) | |||

| 44kg(500(W)×1000(H)×78(D) | 44kg(500(W)×1000(H)×78(D) | ||

| Floor support weight (kg/piece) | 2kg | 2kg | |

| Weight(kg/Outer packing wooden box plus box body) | 6 in1 wooden carton, | 6 in1 wooden carton, | |

| 150kg (500*1000mm Cabinet) | 150kg (500*1000mm Cabinet) | ||

| Outer packing wooden carton dimension(L x H x D ) | 6 in 1 wooden carton, | 6 in 1 wooden carton, | |

| SPEC:1070X680X570mm ( L x H x D ) | SPEC:1070X680X570mm ( L x H x D ) | ||

| Cabinet size(500(W)×1000(H)×78(D) | Cabinet size(500(W)×1000(H)×78(D) | ||

| Pixel density(dot/㎡) | 160000 | 147456 | |

| Protection level | Indoor(front IP65,back IP43) | Indoor(front IP65,back IP43) | |

| Cabinet flatness(mm) | ≤1 | ≤1 | |

| White balance brightness(nits) | ≥1300(CCT 9500K) | ≥1300(CCT 9500K) | |

| Color temperature(K) | 3200—9300Adjustable | 3200—9300Adjustable | |

| Horizontal perspective( °) | >120 | >120 | |

| Center distance deviation of luminous point | <3% | <3% | |

| Brightness uniformity | ≥97% | ≥97% | |

| Chromaticity uniformity | Within ±0.003Cx,Cy | Within ±0.003Cx,Cy | |

| Max contrast | 6000:01:00 | 6000:01:00 | |

|

Electrical parameters

|

Power consumption (A/unit module) | DC 6∽7 | DC 6∽7 |

| Peak power consumption | 400 ;800 | 400 ;800 | |

| (W/cabinet;W/㎡) | |||

| Average power consumption(W/cabinet;W/㎡) | 200;400 | 164;267 | |

| Power requirements | AC220V(50-60Hz) | AC220V(50-60Hz) | |

|

Processing performance

|

Pixel sharing technology | Yes | Yes |

| Drive way | Constant current drive | Constant current drive | |

| Frame change frequency(Hz) | 50&60 | 50&60 | |

| Refresh rate(Hz) | ≥1920/≥3840/7680 | ≥1920/≥3840/7680 | |

| @60HzFrame rate signal source | |||

|

Ambient

|

Lifespan | 100000 hours | 100000 hours |

| Work temperature | -20 — 55℃ | -20 — 55℃ | |

| Storage temperature | -30 — 60℃ | -30 — 60℃ | |

| Humidity (RH)no condensation | 10 - 90% | 10 - 90% | |

| Storage temperature(RH)no condensation | 10 - 95% | 10 - 95% | |

| Screen thickness | module+cabinet:78mm,screen+floor support:150∽170mm adjustable | module+cabinet:78mm,screen+floor support:150∽170mm adjustable | |

| Defective ratio | ≤4/100000 | ≤4/100000 | |

| Unit module splicing gap | Uniformity and ≤2mm | Uniformity and ≤2mm | |

| Best view distance | 3-15m | 3-15m | |

| View angle | horizontal>120° | horizontal>120° | |

| Surface flatness | Max tolerance≤1mm | Max tolerance≤1mm | |

| Screen surface color | Uniformity 95%(white transparent or tea color) | Uniformity 95%(white transparent or tea color) | |

| Brightness Uniformity | 95% | 95% | |

| Brightness | ≥1300CD/㎡ | ≥1300CD/㎡ | |

| Circuit layout | Light-driven integrated SMD technology, evenly distributed light-emitting pixels, suspended circuit board design, no stress, reasonable layout, standard and beautiful wiring, stable and reliable | Light-driven integrated SMD technology, evenly distributed light-emitting pixels, suspended circuit board design, no stress, reasonable layout, standard and beautiful wiring, stable and reliable | |

| Loading bearing capacity | 1.5 tons /㎡ | 1.5 tons /㎡ | |

| 1545/N(single point ) | 1545/N(single point ) | ||

| Friction coefficient | Static friction coefficient 0.79/Us | Static friction coefficient 0.79/Us | |

| Dynamic friction coefficient 0.71/UD | Dynamic friction coefficient 0.71/UD | ||

| Certifications | CE、FCC、 ROHS、 CCC 、Certification of load-bearing, waterproof, heating, friction coefficient, etc. | CE、FCC、 ROHS、 CCC 、Certification of load-bearing, waterproof, heating, friction coefficient, etc. |